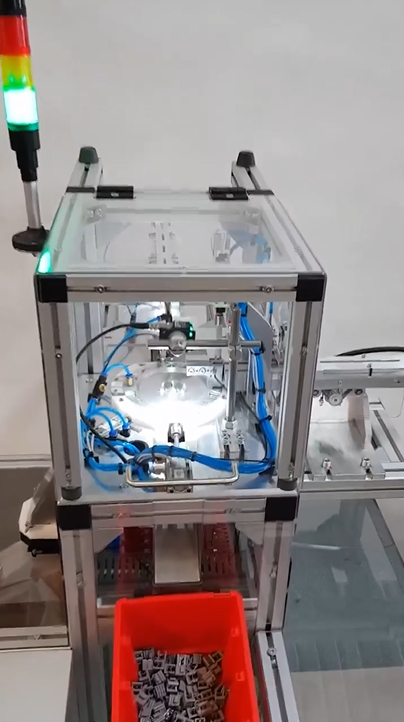

Machine for nailing metal clips with plastic elements

The aim of the project is to automate the previously manual process of assembling plastic and metal elements. The product itself is widely used in every industry using cable management systems, so the requirements for the quality and efficiency of the process are very high. The device is based on two vibratory feeders feeding semi-finished products onto a rotary table. After loading, the elements are nailed, quality checked using a Keyence vision sensor, the correct piece is marked and thrown into a bag. Depending on the version of the device, a bag changer is also available, which increases the total efficiency of the process.