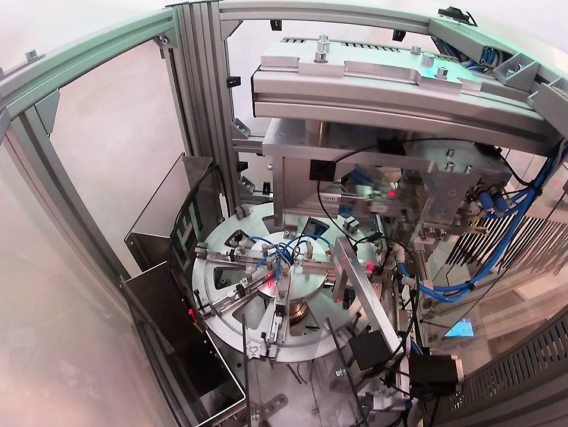

Machine for connecting cable ties with a socket

The presented device is used for mounting clamps with a mounting socket, with a capacity of up to 2500 pieces per hour. High efficiency is possible thanks to the use of a rotary table, driven by a servo drive. Semi-finished products are fed to the device using vibratory feeders. The table is divided into three working zones, in which pneumatic actuators work – a zone for stuffing, dumping of incorrectly stuffed clamps, dumping of correct details.

The process starts after the queue sensor detects the mounting socket. The socket is moved by a pneumatic actuator to the holder in which the presence sensor is installed. Then, after confirming the presence, the socket is moved to the first zone of the rotary table, where the clamp is stuffed into the socket. The clamp is mounted in the socket to the height desired by the customer, which is then checked by a set of optical sensors. Depending on the reading, the program decides which of the next zones the finished product should go to. The device is able to count the number of products produced.